What are the specific complex post-processing techniques for custom zamak accessories for cosmetic packaging? →

What are the specific complex post-processing techniques for custom zamak accessories for cosmetic packaging? →

Mechanical Polishing: Sandblasting, Grinding/Polishing, Barrel Finishing

Pre-finishing Surface Preparation: Remove surface oil, grease, and release agent residues; Eliminate oxide films.

Surface Treatment Processes (For enhance surface decorativeness, corrosion resistance, wear resistance, and service life):

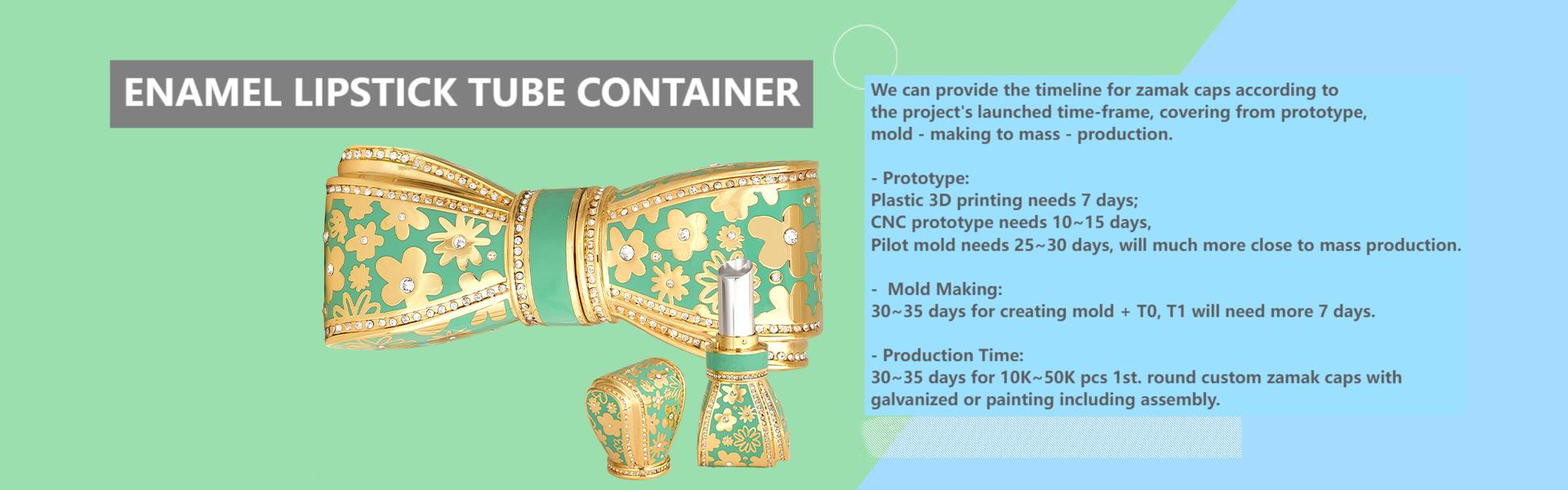

Exquisite Epoxy/Enamel Coating: Achieve luxurious packaging effects.

Zinc Plating/Painting/PVD Coating: Provide diverse surface finishes.

Water Transfer Printing/Hot Stamping/UV Printing/Silk Screening/Pad Printing: Realize versatile patterns and text.

These post-processing techniques can help you achieve desired glossy or matte effects and meet personalized packaging requirements.

For iPackagePro's Packaging Solution for zamak products, we tailor post-processing is comprehensively planned based on design needs, including balancing cost and performance, environmental sustainability(e.g.,nickel-free passivation), and compatibility with subsequent processing. Optimal solutions for multi-process combinations deliver optimal functionality and economy.

Whether you need high-precision mechanical polishing or eco-friendly surface treatments, iPackagePro delivers optimal functionality and cost efficiency through multi-process integration. [Contact Now] for a free process quotation!

Website: www.ipackagepro.com | www.zamakpro.com

Email: [email protected]

Phone: +86-13433099901 (WhatsApp/WeChat)

The Ultimate Guide to Purchasing Custom Zamak Cosmetic Packaging & Accessories Solutions to Elevate Your Fragrance&Cosmetic Brands : OEM & ODM & NDP Turnkey Support

The Ultimate Guide to Purchasing Custom Zamak Cosmetic Packaging & Accessories Solutions to Elevate Your Fragrance&Cosmetic Brands : OEM & ODM & NDP Turnkey Support

Hand-enameled Process

Hand-enameled Process

Quality Control

Quality Control